We can provide not any pellet mill equipments for you but complete wood pellet line and equipment replacement services.

- Without green leaves how lotus can be fragrance;

- without seagulls flying how the sea show the vastness;

- without pellet mill equipments how we own perfect wood pellets energy!

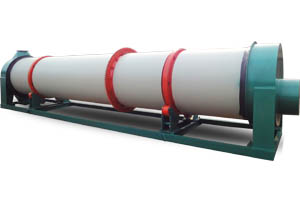

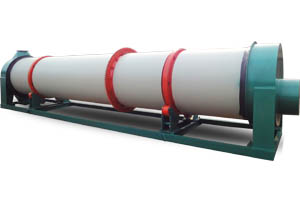

wood pellet dryer

The moisture content of raw material is an important factor to influence the quality of pellets. Through numerous practical experiments, the appropriate moisture content for pelletizing is controlled about 11%-16%, if the moisture content of material exceeds 16%, it will be difficult to pelletize in pellet mill. So wood pellet dryer is a significant process in pellet production line.

Rotary Drum Dryer

Technical Parameters

|

Model |

Diameter(mm) |

Length(m) |

Power(kw) |

Speed of rotation (r/min) |

|

HZG6 |

600 |

4,5,6,7,8 |

3-5.5 |

3-20 adjustment |

|

HZG8 |

800 |

4,5,6,7,8,9,10 |

5.5-7.5 |

|

HZG10 |

1000 |

6,7,8,9,10,11,12 |

5.5-7.5 |

|

HZG12 |

1200 |

6,8,10,12,14,16 |

7.5-11 |

|

HZG15 |

1500 |

8,10,12,14,16,18 |

11-15 |

|

HZG18 |

1800 |

8,10,12,14,16,18,20 |

15-18.5 |

|

HZG22 |

2200 |

10,12,14,16,18,20,22,25 |

18.5-22 |

|

HZG24 |

2400 |

12,14,16,18,20,22,25 |

22-30 |

Other Wood Pellet Dryers

|

|

|

Single Layer |

|

|

Hot Air Inlet |

|

Single Layer Wood Pellet Dryer |

|

|

|

Three Layers |

|

|

Wet Material Inlet |

|

Three Layer Wood Pellet Dryer |

Why We Need A Wood Pellet dryer?

|

The rotary drum dryer is a type of pellet mill equipment to reduce the moisture content of raw material like sawdust, rice husk, corn stover and other biomass materials. The dryer uses steam to heat air and contact material to remove certain degree of moisture. The dryer is apt to handle large quantity of raw materials in complete pellet plant for further process.

-

It is capable of consolidating, roasting and drying.

-

Adopts converter motor for a wide speed ranges, efficient time control, good drying performance.

-

Inlet steam pipe is sealed by the advanced swivel joint avoiding steam and water leakage.

-

Applicable to shrimp feed that has a high standard for roasting and water proofing.

-

Continuous rotation of biomass material ensures high quality final product.

|