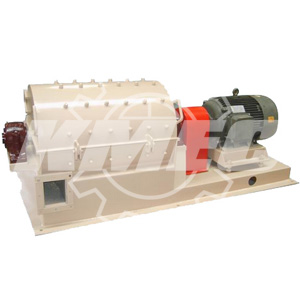

wood chipper machine

The wood chipper is designed to chip the wood logs, bamboo, wood branches and other large size materials into chipper. It is widely utilized in the furniture processing factory, medium density board and complete wood pellet plant.

Technical Parameters of Wood Chipper Machine

| Model | BX213 | BX215 | BX216 |

|---|---|---|---|

| Rotor Diameter(mm) | 300 | 500 | 650 |

| Number of rotor knives(pieces) | 2 | 2 | 2 |

| Feed opening(mm) | 120*300 | 180*400 | 240*540 |

| Rotor Speed(Rph) | 730 | 592 | 590 |

| Feed Speed(m/min) | 38 | 38 | 38 |

| Stock processed max diameter(mm) | 90 | 160 | 200 |

| Chip length(mm) | 26 | 35 | 35 |

| Capacity(m3/h) | 3-5 | 4-5 | 12 |

| Main drive motor power(kw) | 30 | 45 | 55 |

| Feed roller motor power(kw) | 1.1*2 | 2.2*2 | 3*4/4*1 |

| Weight(t) | 1.2 | 2.9 | 4.07 |

| Overrall dimensions(L*W*H)(mm) | 3680*870*900 | 1540*1240*1020 | 1980*1950*1250 |

Detail Parts of Wood Chipper

|

|

|

| Drums | Knife | Tooth Roller |

|---|

The wood chipper is drum design and made of high strength steel plates to make sure its durability. The knives are connecting with the rotor through a clamping plate. The upper roller assembly can float up and down over the materials to be cut in a certain range depending on the thickness of raw materials.

Salient Features of Wood Chipper |

|---|

|