ring die pellet mill

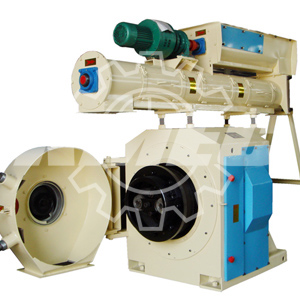

Ring die pellet mill is main pellet mill equipments. It is mainly used to turn various kinds of agro-forestry wastes into biomass pellets fuel. Generally, the ring die pellet mill includes feeder system, screw conditioner, gearbox, ring die and lubrication system. The raw materials are transferred to screw conditioner by a screw feeder. Then different raw materials are fully mixed in the conditioner. Therefore, the screw conditioner plays an important role in softening raw materials by using steam. After softening, the raw materials are sent to pelletizing chamber by feeder. The pressure from rollers in the chamber force the raw materials into the holes of the ring die, the pellets are formed. After pelletizing, the large pellets can be cut according to customers’ different requirements.

Technical Parameters

| Model |

Main motor power(Kw) |

Capacity(t/h) |

Feeding motor power(Kw) |

Conditioner motor power(Kw) |

Diameter of die(mm) |

Pellet diameter (mm) |

|---|---|---|---|---|---|---|

| KMPM25 | 7.5*2 | 0.2-0.3 | 0.75-0.55 | 2.2 | 250 | 4-8 |

| KMPM32 | 37 | 0.3-0.6 | 0.75-0.55 | 2.2 | 320 | 4-8 |

| KMPM35 | 55 | 0.5-0.8 | 0.75-0.75 | 2.2 | 350 | 4-8 |

| KMPM40 | 75 | 0.7-1.1 | 1.5+0.75 | 2.2 | 400 | 4-8 |

| KMPM42 | 110 | 1.0-1.5 | 1.5+0.75 | 5.5 | 420 | 4-8 |

| KMPM508 | 132/160 | 2.0-3.0 | 1.5+0.75 | 7.5 | 508 | 4-8 |

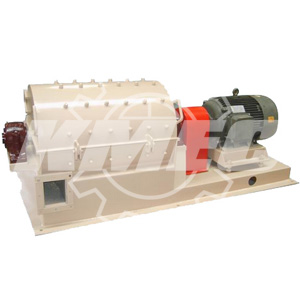

New Design Style of Ring Die Pellet Mill

|

|

| KMPM350 | KMPM520 |

|---|

Technical Parameters

| Model | Main motor power(kw) | Capacity(kg/h) | Feeding motor power(kw) | Conditioner motor power(kw) |

|---|---|---|---|---|

| KMPM350 | 55 | 500 | 0.55 | 5.5 |

| KMPM420 | 90 | 800-1000 | 0.55 | 5.5 |

| KMPM520 | 75*2 | 1500-2000 | 0.55 | 5.5 |

| KMPM650 | 110*2 | 2500-3000 | 1.5 | 7.5 |

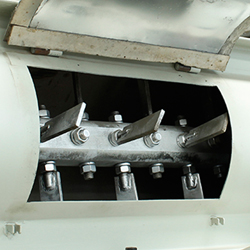

Main Parts of Ring Die Pellet Mill

|

|

| Magnegic Separator | Automatic Lubrication System |

|---|---|

|

|

| Mositure Adjust Device | Overload Discharge durng Pelletizing System |

Features of Ring Die Pellet Mill

|

The lubrication system adopts a tracing and inspection system controlled by a microcomputer. When the temperature of the bearings exceed normal temperatures, the microcomputer will start the auto-lubrication system for lubrication—thereby conveniently ensuring smooth functioning of the rollers. There is also the option to lubricate by hand. |

| Lubrication System |

|---|

|

The drive gear is a precision-made transmission mechanism. The bearings are sourced from Sweden. Compared with the previous bolt-fastening way, the ring die adopts a hoop fastening method which increases the speed of discharge. As a result, the capacity is 10-15% higher than the belt transmission structure. |

| Drive Gear |

|---|

|

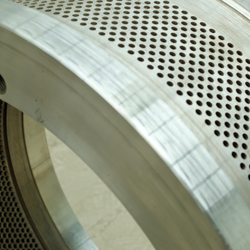

The ring die and roller both adopts alloyed steel. The heat treatment process utilizes carburization treatment that increases the depth of hard-facing to 2 mm As a result, this not greatly improves the anti-abrasion properties of the ring die and roller but saves on replacement costs. |

| Ring Die |

|---|