wood hammer mill

Wood crusher plays a key role in crushing raw materials for complete pellet production line. Before purchasing wood crusher, you need to have a clear understanding about your materials dimension. Then you can choose the appropriate machine for your wood pellet plant. According to a variety of material size, we supply you two types of wood crusher machine: wood crusher and hammer mill.Wood Crusher

|

Wood crusher is ideal pellet mill equipment for complete pellet production line that is used to process wood log, blocks and wood trimming etc. with size less than 200mm. Through wood crusher processing, the size of raw material can be crushed between 3 mm and 5 mm which is suitable for pelletizing. | ||

| Model | MFSP56*60 | MFSP70*60 | MFSP66*80 |

|---|---|---|---|

| Powder(Kw) | 37 | 75 | 90 |

| Capacity(f/h) | 1 | 2 | 2.5 |

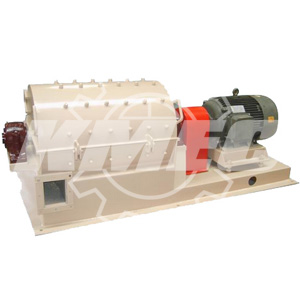

Hammer Mill

|

Hammer mill is another crusher machine for complete pellet production line. It is mainly proper to crush raw material with size less than 50mm. The output size also reaches diameter 3-5mm so as to meet further processing. The hammer mill uses collision between the high-speed hammers and materials to crush materials. In addition, the hammer mill has simple structure, easy operation and low power consumption. | ||

| Model | FSPZ56*40 | FSPZ60*45 | FSPZ132*50 |

|---|---|---|---|

| Powder(KW) | 37 | 55 | 110 |

| Capacity(t/h) | 1 | 2 | 4 |

Detailed Parts of Hammer Mill

|

|

|

| Screen | Hammers | Screen Holder |

|---|

Photo Display of Raw Material

|

|

| Raw Material before Crushing | Raw Material after Crushing |

|---|

Features |

|---|

|