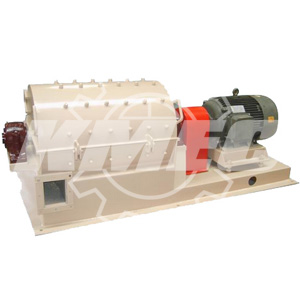

pellet mill cooler

Pellet mill cooler is key pellet mill equipment in the pellet production line, which mainly cool the wood pellets from pellet mill with high temperature and much moisture. The direction of air in the cooler is opposite to the flowing pellets in order to evaporate moisture from the wood pellets. When the moisture evaporation, the heat of wood pellets will also be removed from the pellets.SLNF Series Pellet Mill Cooler

|

Necessities of pellet mill cooler for complete pellet plant |

|---|---|

|

Technical Parameters

| Model | SLNF 15x15 | SLNF 19x19 | SLNF 19x24 | SLNF 24x24 | SLNF 24x28 | SLNF 28x28 |

|---|---|---|---|---|---|---|

| Capacity(t/h) | 5 | 10 | 15 | 20 | 25 | 30 |

| Power(kw) | 0.75+0.75 | 1.5+1.5 | 1.5+1.5 | 2.2+2.2 | 2.2+2.2 | 2.2+3 |

SKLN Series Pellet Mill Cooler

|

Model | SKLN 14 | SKLN 19 | SKLN 22 |

|---|---|---|---|---|

| Cooling Volume (m3) | 2.5 | 5 | 8 | |

| Output (t/h) | 1-2 | 3-5 | 6-8 | |

| Air-absorbed (m3/h) | 10000 | 15000 | 27000 | |

| Power (kw) | 3 | 3 | 2.5+1.5 |

Detail Parts of Pellet Mill Cooler

|

|

|

| Inspection Window | Level Indicator | Discharger |

|---|

Outstanding Features |

|---|

|

.