We can provide not any pellet mill equipments for you but complete wood pellet line and equipment replacement services.

- Without green leaves how lotus can be fragrance;

- without seagulls flying how the sea show the vastness;

- without pellet mill equipments how we own perfect wood pellets energy!

complete wood pellet line

Complete wood pellet line is the process of converting wood wastes into wood pellets fuel. This is mainly used for commercial purpose. The wood pellets are utilized for burning, which meet not families’ heating and cooking but provide fuel for industry. Wood wastes are one of the most common used materials for pelletized.

Different Scale for Wood Pellet Line

|

|

Introduction of Complete Wood Pellet Line

|

Raw material

|

|

Wood pellet fuel is usually made from any kinds of agro-forestry wastes like sawdust, wood chips, wood shavings, corn stover, wheat straw, leaf, rice husk, peanut shells, bagasse etc. |

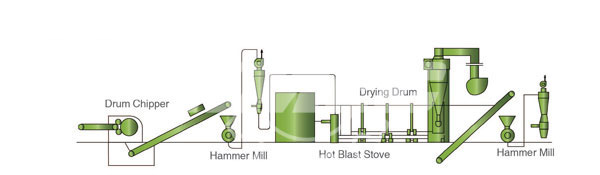

Process of complete wood pellet line

|

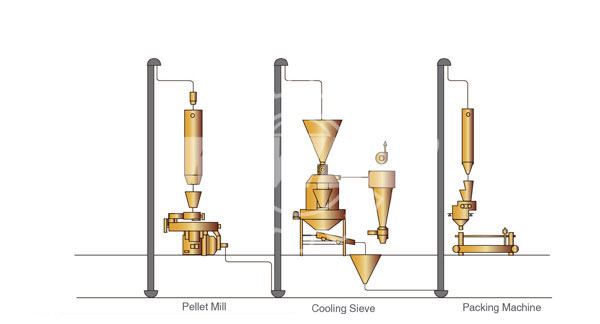

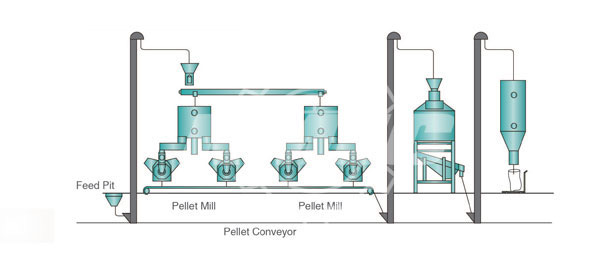

In complete wood pellet line, it usually contains three main processes: the material should be pretreated like crushed and dried; pretreated materials are compressed and form various size of wood pellets according to customers’ requirements; finally these wood pellets are packed with bagging machine after cooling. |

Detailed for complete wood pellet line

|

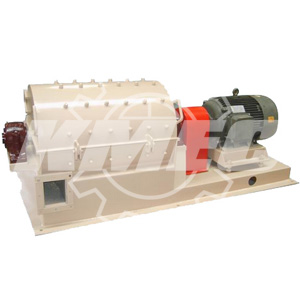

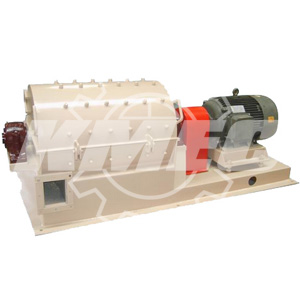

When the dimensions of the raw materials are larger than 50*50*10mm, a wood crusher must be used to crush the materials into smaller pieces. A hammer mill is then able to grind the material into segments less than 3mm in length.

|

|

|

Hammer Mill |

Wood Crusher |

The appropriate moisture content for pelletizing is about 13%-15%. Our rotary drum dryer consists of a stove and a main dryer component which can cut down the moisture content from 60%-10%. Our stove is fueled by coal which saves the consumption of electricity.

The ring die pellet mill provided by KMEC can make pellets continuously in most adverse conditions. The key features of our design are high quality, durability and low maintenance costs. Considering its functionality, our primary components adopt alloyed steel.

After pelletizing process, the temperature of biomass pellets is very high about 80℃. The pellets’ moisture content is typically about 15%. With the help of counterflow cooler, moisture content of wood pellets can be reduced to 3-4% simultaneously decreasing the temperature.

After cooling, the pellets must be packed with plastic bag in order to avoid humid and break. So the pellet packing machine is necessary for pellets. It is better to store and transport. The pellet packing machine includes two types: semi-auto packing machine and auto-sealing packing machine. The clients can select proper pellet packing machine depending on your practical needs.

|